Characteristics and division of cleanroom air conditioning: The cleanroom air filters have diverse characteristics in classification and configuration to meet the requirements of different cleanliness levels. The following is a detailed answer to the classification and configuration of cleanroom air filters.

1. Classification of air filters

Classification by performance:

According to relevant Chinese standards, filters can be divided into six categories: primary filter, medium filter, sub-hepa filter, hepa filter, ulpa filter. These classifications are mainly based on performance parameters such as filter efficiency, resistance and dust holding capacity.

In European standards, air filters are divided into four grades: G, F, H, and U, where G represents primary filter, F represents medium filter, H represents hepa filter, and U represents ulpa filter.

Classification by material: Air filters can be made of synthetic fiber, ultra-fine glass fiber, plant cellulose and other materials, or they can be filled with natural fiber, chemical fiber and artificial fiber to make filter layers.

Filters made of different materials differ in efficiency, resistance and service life.

Classification by structure: Air filters can be divided into various structural forms such as plate type, folding type and bag type. These structural forms have their own characteristics and are suitable for different application scenarios and filtering needs.

2. Configuration of cleanroom air filters

Configuration according to cleanliness level:

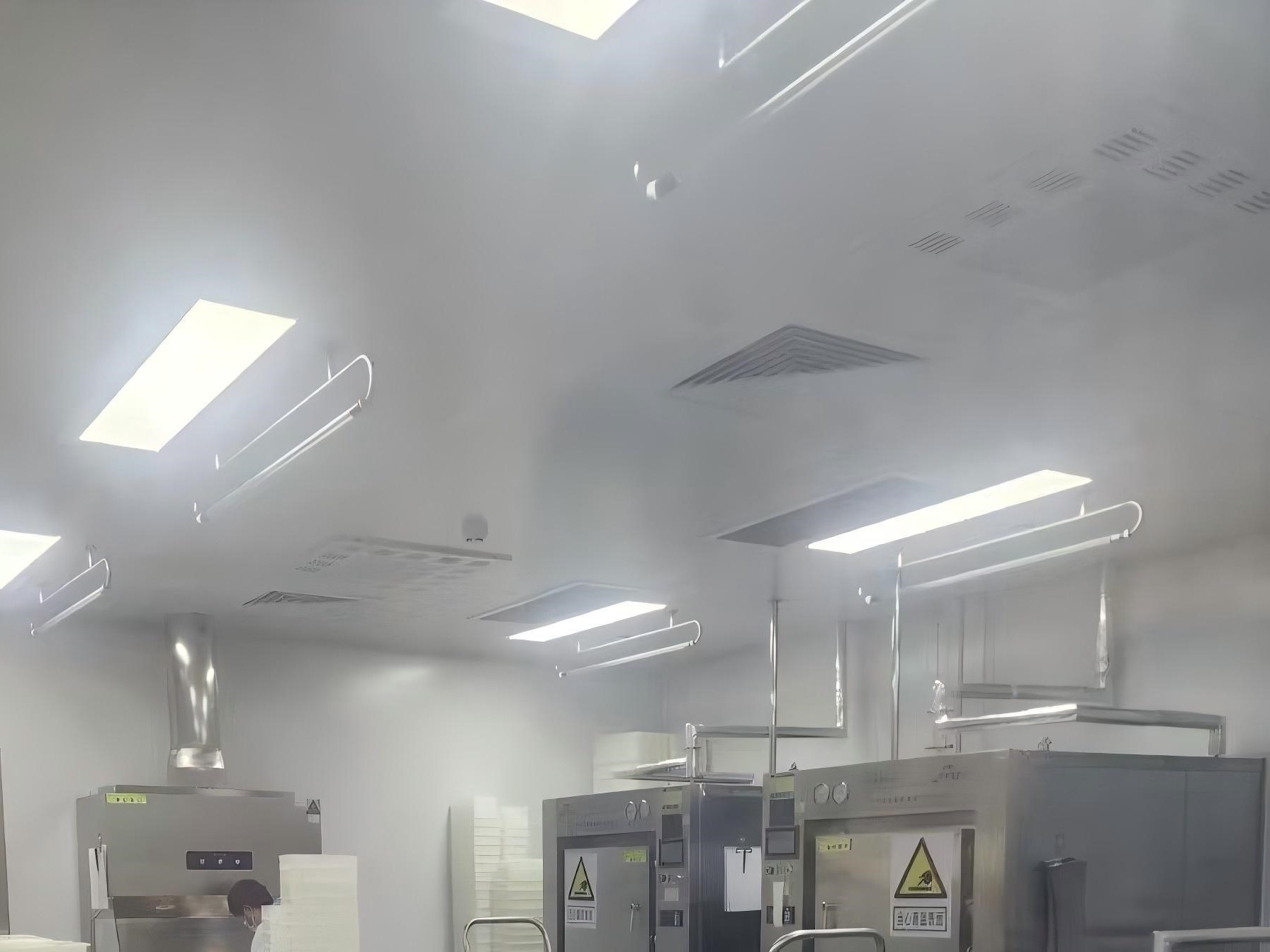

For cleanroom purification systems of class 1000-100,000, three-level air filtration is usually adopted, namely, primary, medium and hepa filters. Primary and medium filters are generally placed in air handling devices, and hepa filters are located at the end of the purification air conditioning system.

For purification air conditioning systems of class 100-1000, primary, medium and sub-hepa filters are usually set in the fresh air handling device, and hepa filters or ulpa filters are set in clean room circulating air system. Hepa filters are generally also located at the end of the purification air conditioning system.

Configuration according to production process:

In addition to considering the cleanliness level, air filters also need to be configured according to the special requirements of the production process. For example, in microelectronics industry, precision instruments and other industries, hepa or even ulpa air filters are needed to ensure the cleanliness of the production environment.

Other configuration points:

When configuring air filters, you also need to pay attention to issues such as the installation method, sealing performance and maintenance management of the air filters. Ensure that the filter can operate stably and reliably and achieve the expected filtering effect.

Cleanroom air filters are classified into primary, medium, hepa, sub-hepa, hepa and ulpa filter. The configuration needs to be reasonably selected and configured according to the cleanliness level and production process requirements. By scientifically and reasonably configuring air filters, the cleanliness level of the cleanroom can be effectively improved, ensuring the stability and reliability of the production environment.

Post time: Jul-23-2025