Clean room doors are an important component of clean rooms, and are suitable for occasions with cleanliness requirements such as clean workshops, hospitals, pharmaceutical industries, food industries, etc. The door mold is integrally formed, seamless, and corrosion-resistant. A good clean room door can tightly seal the space, retain indoor clean air, exhaust polluted air, and save a lot of energy. Today we will talk about this important clean room door for the clean room.

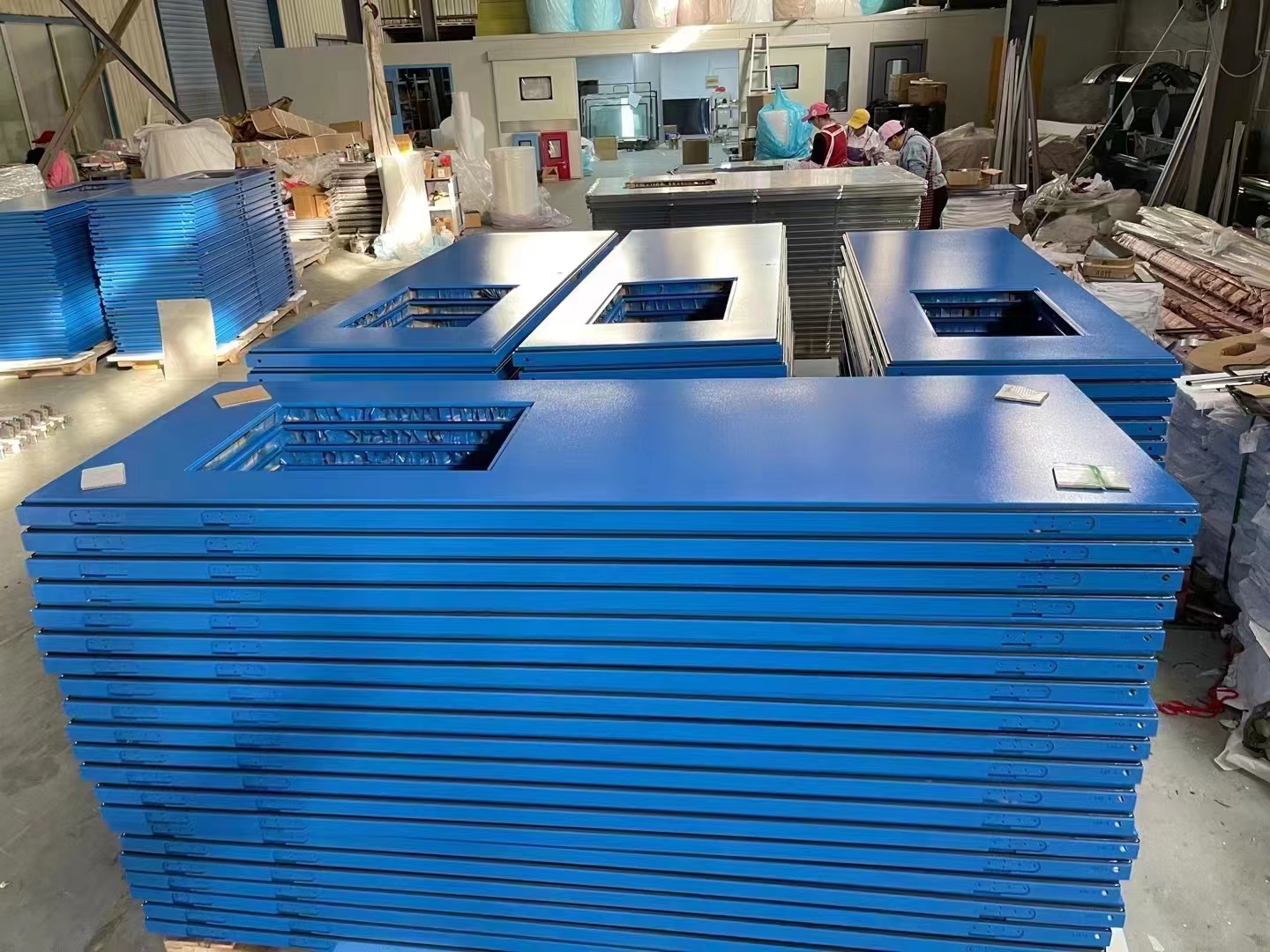

Clean room doors can be roughly divided into three product series based on material: steel doors, stainless steel doors and HPL doors. Clean room door core materials generally use high-quality flame-retardant paper honeycomb or rock wool to ensure the strength and flatness of the clean room door.

Structural form: single door, unquel door, double door.

Direction discrimination: clockwise right opening, counterclockwise left opening.

Installation method: "+" shaped aluminum profile installation, double clip type installation.

Door frame thickness: 50mm, 75mm, 100mm (customized according to requirements).

Hinge: 304 stainless steel semi circular hinge, can be used for a long time and high frequency, without dust; The hinge has high strength, ensuring that the door leaf does not sag.

Accessories: door locks, door closer and other hardware switches are light and durable.

View window: There are multiple options for double-layer right angle window, round corner window, and outer and inner circle window, with 3C tempered glass and built-in 3A molecular sieve to prevent fogging inside the window.

Door sealing: The door leaf is made of polyurethane adhesive foam, and the bottom lifting dust sweeping strip has excellent sealing performance.

Easy to clean: The clean room door material has high hardness and is resistant to acid and alkali. For some difficult to clean dirt, a cleaning ball or cleaning solution can be used for cleaning.

Due to GMP's requirements for a clean room environment, high-performance clean doors can establish air locks between spaces, regulate the pressure in clean room, and make the clean room environment sealed and controlled. Choosing a suitable clean room door not only considers the surface smoothness, door panel thickness, airtightness, cleaning resistance, windows, and anti-static surface of the door, but also includes high-quality accessories and good after-sales service.

With the continuous improvement of production environment cleanliness requirements in the pharmaceutical industry, the demand for clean room doors is also constantly increasing. As a provider of clean room turnkey solutions in this industry, we select environmentally-friendly raw materials, implement strict process standards, and strive to provide higher quality and reliable products for clean room industry. We are committed to bringing clean rooms to every industry, organization and person.

Post time: May-31-2023