A relatively complete automatic control system/device should be installed in clean room, which is very beneficial to ensure the normal production of clean room and improve the operation and management level, but the construction investment needs to be increased.

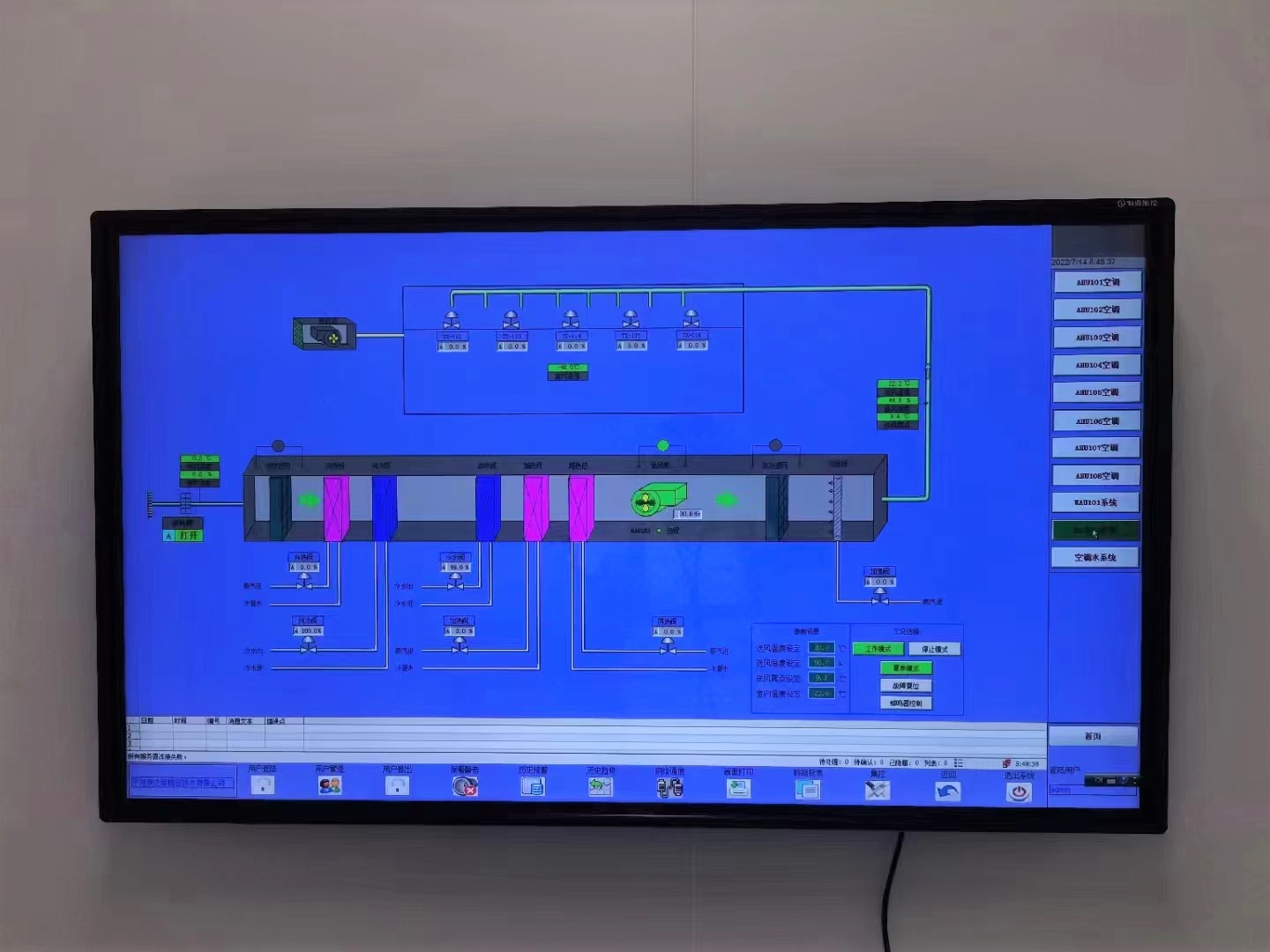

Various types of clean room include the monitoring of air cleanliness, temperature and humidity, the pressure difference, high-purity gas and pure water, gas purity and pure water quality, and other requirements and technical parameters are different and the scale and area of clean rooms in various industries are also very different, so the function of the automatic control system/device should be determined according to the specific conditions of clean room project, and it should be designed into various types of monitoring and control systems. The clean room is designed as a distributed computer control and monitoring system.

The automatic control and monitoring system of the modern high-tech clean room represented by the microelectronics clean room is a comprehensive system integrating electrical technology, automatic instrumentation, computer technology and network communication technology. Only by using various technologies correctly and reasonably, The system can meet the required control and supervision requirements.

In order to ensure the strict requirements of the electronics clean room of on the control of the production environment, the control systems of the public power system, purification air conditioning system, etc. should first have high reliability.

Secondly, for different control equipment and instruments, it is required to be open to meet the requirements of realizing the network control of the whole plant. The production technology of electronic products is developing rapidly, and the design of the automatic control system of the electronics clean room should be flexible and expandable to meet the changes in the control requirements. The distributed network structure has a good human-computer interaction interface, which can better realize the detection, monitoring and control of the production environment and various power public equipment, and can be applied to clean room control using computer technology. When the parameter index requirements of the clean room are not very strict, conventional instruments can also be used for control. But no matter which method is used, the control accuracy should meet the production requirements, and can achieve stable and reliable operation, and can realize energy saving and emission reduction.

Post time: Aug-28-2023