Filters are divided into hepa filters, sub-hepa filters, medium filters, and primary filters, which need to be arranged according to the air cleanliness of the clean room.

Filter type

Primary filter

1. The primary filter is suitable for the primary filtration of air conditioning systems, mainly used for filtration 5μm dust particles above.

2. There are three types of primary filters: plate type, folding type, and bag type.

3. The outer frame materials include paper frame, aluminum frame, and galvanized iron frame, while the filtering materials include non-woven fabric, nylon mesh, activated carbon filter material, metal mesh, etc. The protective mesh includes double-sided plastic sprayed iron wire mesh and double-sided galvanized iron wire mesh.

Medium filter

1. Medium efficiency bag filters are mainly used in central air conditioning and centralized air supply systems, and can be used for intermediate filtration in air conditioning systems to protect the lower level filters in the system and the system itself.

2. In places where there are not strict requirements for air purification and cleanliness, the air treated by a medium efficiency filter can be directly delivered to the user.

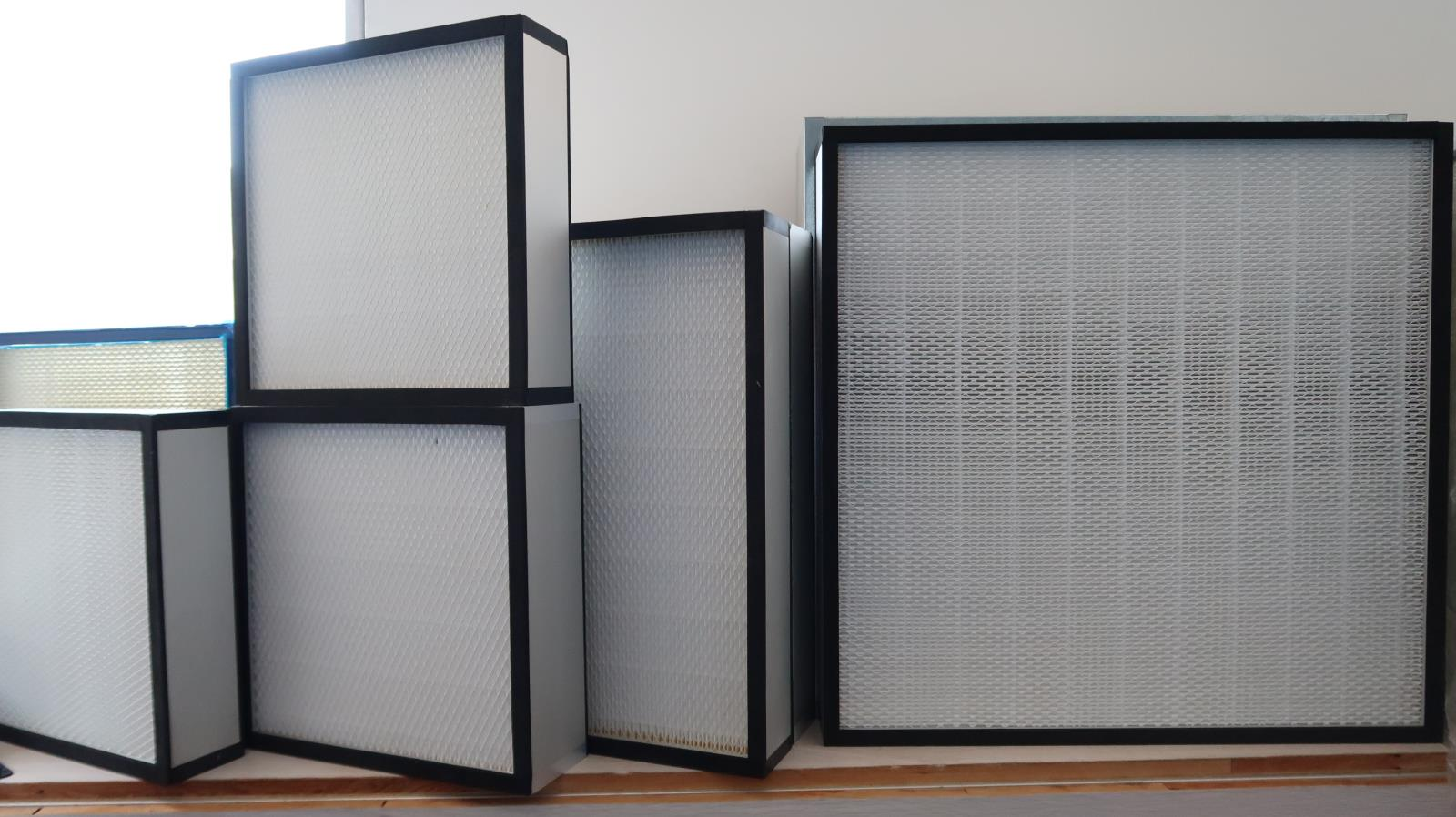

Deep pleat hepa filter

1. The filter material with a deep pleat hepa filter is separated and folded into shape using paper foil that is folded into folds using specialized automatic equipment.

2. Larger dust can be accumulated at the bottom of the scene, and other fine dust can be effectively filtered on both sides.

3. The deeper the refraction, the longer the service life.

4. Suitable for air filtration at constant temperature and humidity, allowing for the presence of trace acids, alkalis, and organic solvents.

5. This product has high efficiency, low resistance, and a large dust capacity.

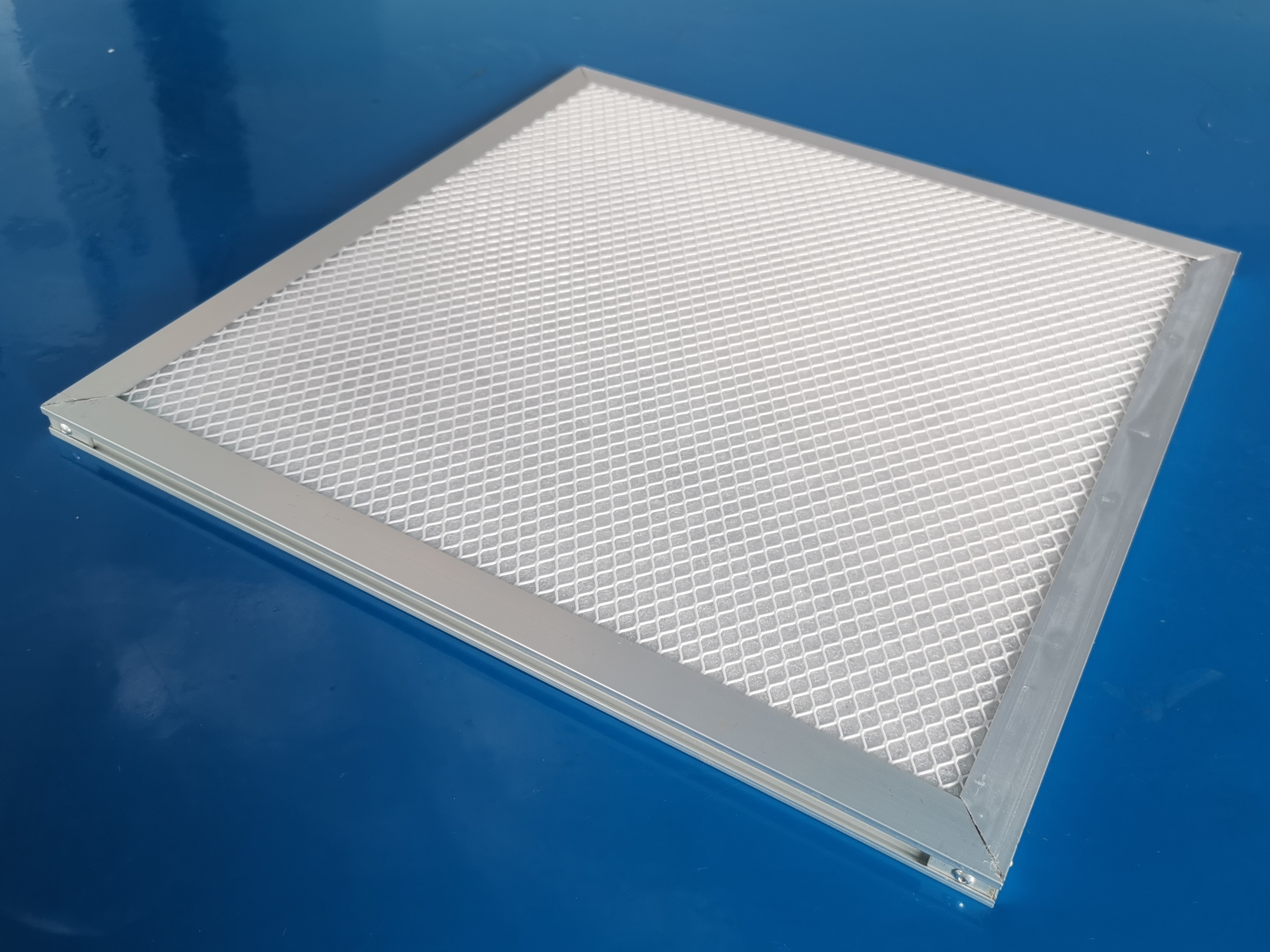

Mini pleat hepa filter

1. Mini pleat hepa filters mainly use hot melt adhesive as a separator for easy mechanized production.

2. It has the advantages of small size, light weight, easy installation, stable efficiency, and uniform wind speed. Currently, large batches of filters required for clean factories and places with high cleanliness requirements mostly use non partition structures.

3. Currently, class A clean rooms generally use mini pleat hepa filters, and FFUs are also equipped with mini pleat hepa filters.

4.At the same time, it has the advantages of reducing the height of the building and reducing the volume of purification equipment static pressure boxes.

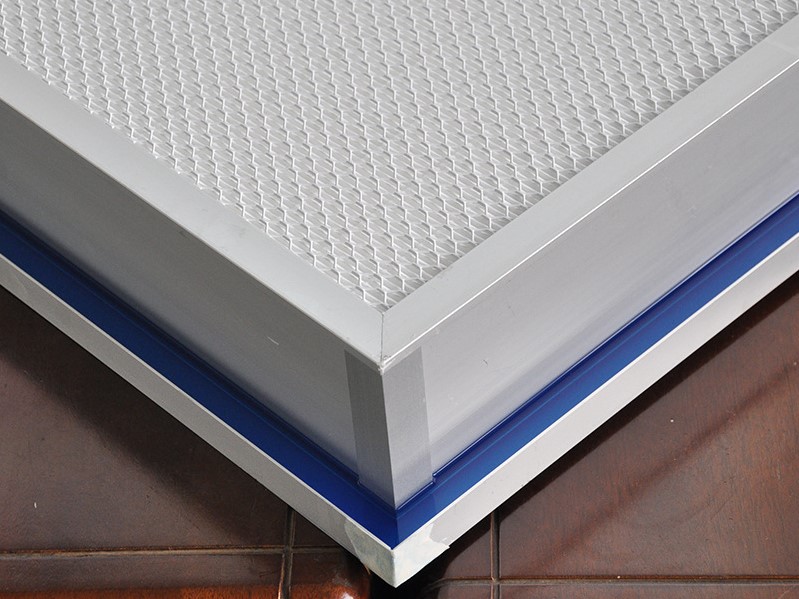

Gel seal hepa filter

1. Gel seal hepa filters are currently widely used filtration equipment in industrial and biological cleanrooms.

2. Gel sealing is a method of sealing that is superior to the commonly used mechanical compression devices.

3. The installation of the gel seal hepa filter is convenient, and the sealing is very reliable, making its final filtration effect superior to ordinary and efficient.

4. The gel seal hepa filter has changed the traditional sealing mode, bringing industrial purification to a new level.

High temperature resistant hepa filter

1. The high temperature resistant hepa filter uses a deep pleat design, and the corrugated deep pleat can accurately maintain.

2. Utilize the filter material to a greater extent with less resistance; The filter material has 180 folded folds on both sides, with two indentations when bent, forming a wedge-shaped box shaped fold at the end of the partition to prevent damage to the filter material.

Selection of filters (advantages and disadvantages)

After understanding the types of filters, what are the differences between them? How should we choose the suitable filter?

Primary filter

Advantages: 1. Lightweight, versatile, and compact structure; 2. High dust tolerance and low resistance; 3. Reusable and cost saving.

Disadvantages: 1. The degree of concentration and separation of pollutants is limited; 2. The scope of application is limited in special environments.

Applicable scope:

1. Mainstream prefilters for panel, folding commercial, and industrial ventilation and air conditioning systems:

Clean room new and return air conditioning system; The automotive industry; Hotels and office buildings.

2. Bag type primary filter:

Suitable for front filtration and air conditioning applications in automotive paint shops in the painting industry.

Medium filter

Advantages: 1. The number of bags can be adjusted and customized according to specific needs; 2. Large dust capacity and low wind speed; 3. Can be used in humid, high airflow, and high dust load environments; 4. Long service life.

Disadvantages: 1. When the temperature exceeds the temperature limit of the filter material, the filter bag will shrink and cannot be filtered; 2. The reserved space for installation should be larger.

Applicable scope:

Mainly used in electronic, semiconductor, wafer, biopharmaceutical, hospital, food industry and other occasions that require high cleanliness. Used for end filtration in air conditioning and ventilation systems.

Deep pleat hepa filter

Advantages: 1. High filtration efficiency; 2. Low resistance and large dust capacity; 3. Good uniformity of wind speed;

Disadvantages: 1. When there is a change in temperature and humidity, the partition paper may have large particles emitting, which can affect the cleanliness of the clean workshop; 2. Paper partition filters are not suitable for high temperature or high humidity environments.

Applicable scope:

Mainly used in electronic, semiconductor, wafer, biopharmaceutical, hospital, food industry and other occasions that require high cleanliness. Used for end filtration in air conditioning and ventilation systems.

Mini pleat hepa filter

Advantages: 1. Small size, light weight, compact structure, and stable performance; 2. Easy to install, stable efficiency, and uniform air velocity; 3. Low operating costs and extended service life.

Disadvantages: 1. The pollution capacity is higher than that of deep pleat hepa filters; 2. The requirements for filter materials are relatively strict.

Applicable scope:

The end air supply outlet, FFU, and cleaning equipment of the clean room

Gel seal hepa filter

Advantages: 1. Gel sealing, better sealing performance; 2. Good uniformity and long service life; 3. High efficiency, low resistance, and large dust capacity.

Disadvantage: The price cost is relatively high.

Applicable scope:

Widely used in clean rooms with high requirements, installation of large vertical laminar flow, class 100 laminar flow hood, etc

High temperature resistant hepa filter

Advantages: 1. Good uniformity of wind speed; 2. High temperature resistance, able to work normally in a high temperature environment of 300 ℃;

Disadvantage: First use, requires normal use after 7 days.

Applicable scope:

High temperature resistant purification equipment and process equipment. Such as pharmaceutical, medical, chemical and other industries, some special processes of high-temperature air supply system.

Filter maintenance instructions

1. Regularly (usually every two months) use a dust particle counter to measure the cleanliness of the purification area using this product. When the measured cleanliness does not meet the required cleanliness, the cause should be identified (whether there are leaks, whether the hepa filter has failed, etc.). If the hepa filter has failed, a new filter should be replaced.

2. Based on the frequency of use, it is recommended to replace the hepa filter within 3 months to 2 years (with a normal service life of 2-3 years).

3. Under the rated air volume usage conditions, the medium filter needs to be replaced within 3-6 months; Or when the resistance of the filter reaches above 400Pa, the filter must be replaced.

4. According to the cleanliness of the environment, the primary filter usually needs to be replaced regularly for 1-2 months.

5. When replacing the filter, the operation should be carried out in a shutdown state.

6. Professional staff or guidance from professional staff is required for replacement and installation.

Post time: Jul-10-2023