The full name of FFU is fan filter unit. Fan filter unit can be connected in a modular manner, which is widely used in clean rooms, clean booth, clean production lines, assembled clean rooms and local class 100 clean room, etc. FFU is equipped with two levels of filtration including prefilter and hepa filter. The fan inhale air from the top of the FFU and filters it through primary and high-efficiency filter. The clean air is sent out at a uniform speed of 0.45m/s±20% on the entire air outlet surface. Suitable for achieving high air cleanliness in various environments. It provides high-quality clean air for clean rooms and micro-environment with different sizes and cleanliness levels. In the renovation of new clean rooms and clean workshop buildings, the cleanliness level can be improved, noise and vibration can be reduced, and the cost can also be greatly reduced. It is easy to install and maintain, and is an ideal clean equipment for dust free clean room.

Why use FFU system?

The following advantages of FFU system have led to its rapid application:

1. Flexible and easy to replace, install, and move

FFU is motorized itself and self-contained modular, match with filters that are easy to replace, so it is not limited by region; In a clean workshop, it can be separately controlled in partition area as needed and replaced or moved as needed.

2. Positive pressure ventilation

This is a unique feature of FFU. Due to its ability to provide static pressure, clean room is positive pressure relative to the outside environment, so that outside particles will not leak into clean area and make sealing simple and safe.

3. Shorten construction period

The use of FFU saves the production and installation of air ducts and shortens the construction period.

4. Reduce operating costs

Although the initial investment in using FFU system is higher than using air duct system, it highlights energy-saving and maintenance-free features in later operation.

5. Space saving

Compared to other systems, the FFU system occupies less floor height in the supply air static pressure box and basically does not occupy clean room inner space.

FFU application

In general, clean room system includes air duct system, FFU system, etc;

Advantages compared to air duct system:

①Flexibility; ②Reusability; ③Positive pressure ventilation; ④Short construction period; ⑤Reducing operating costs; ⑥Saving space.

Clean rooms, which have a cleanliness level of class 1000 (FS209E standard) or ISO6 or above, usually use FFU system. And locally clean environments or clean closet, clean booth, etc, usually also use FFUs to achieve cleanlines requirement.

FFU types

1. Classified according to overall dimension

According to the distance from the center line of the suspended ceiling keel used to install the unit, the module size of the case is mainly divided into 1200*1200mm; 1200*900mm; 1200*600mm; 600*600mm; Non-standard sizes should be customized by customers.

2. Classified according to different case material

Classified according to different casematerials, it is divided into standard aluminum-coated galvanized steel plate, stainless steel plate and power coated steel plate, etc.

3. Classified according to motor type

According to the motor type, it can be divided into AC motor and brushless EC motor.

4.Classified according to different control method

According to control method, AC FFU can be controlled by 3 gear manual switch and EC FFU can be connected by stepless speed regulation and even controlled by touch screen FFU controller.

5. Classified according to different static pressure

According to different static pressure, it is divided into standard static pressure type and high static pressure type.

6. Classified according to filter class

According to filter carried by the unit, it can be divided into HEPA filter and ULPA filter; Both HEPA and ULPA filter can match with a prefilter at air inlet.

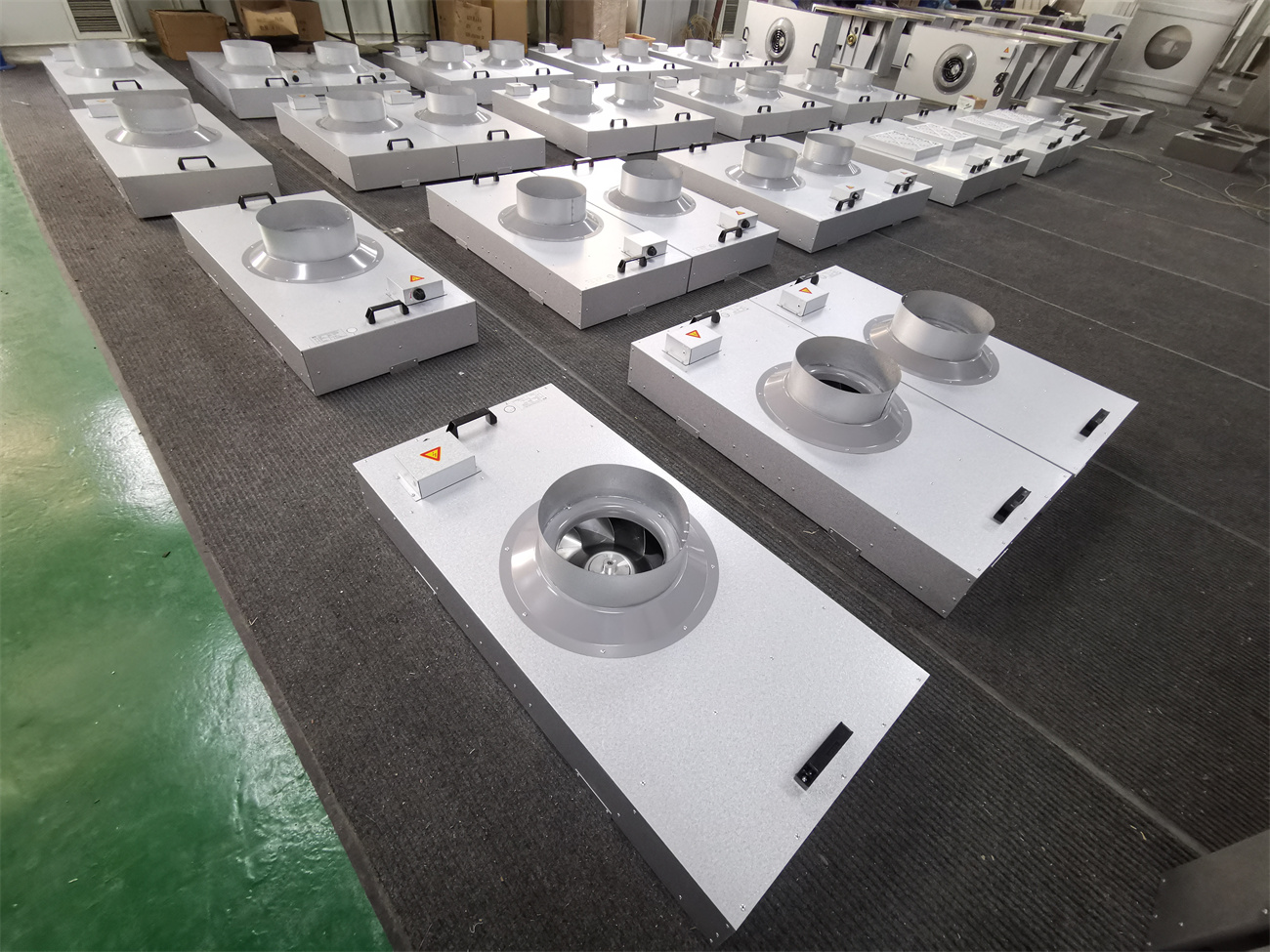

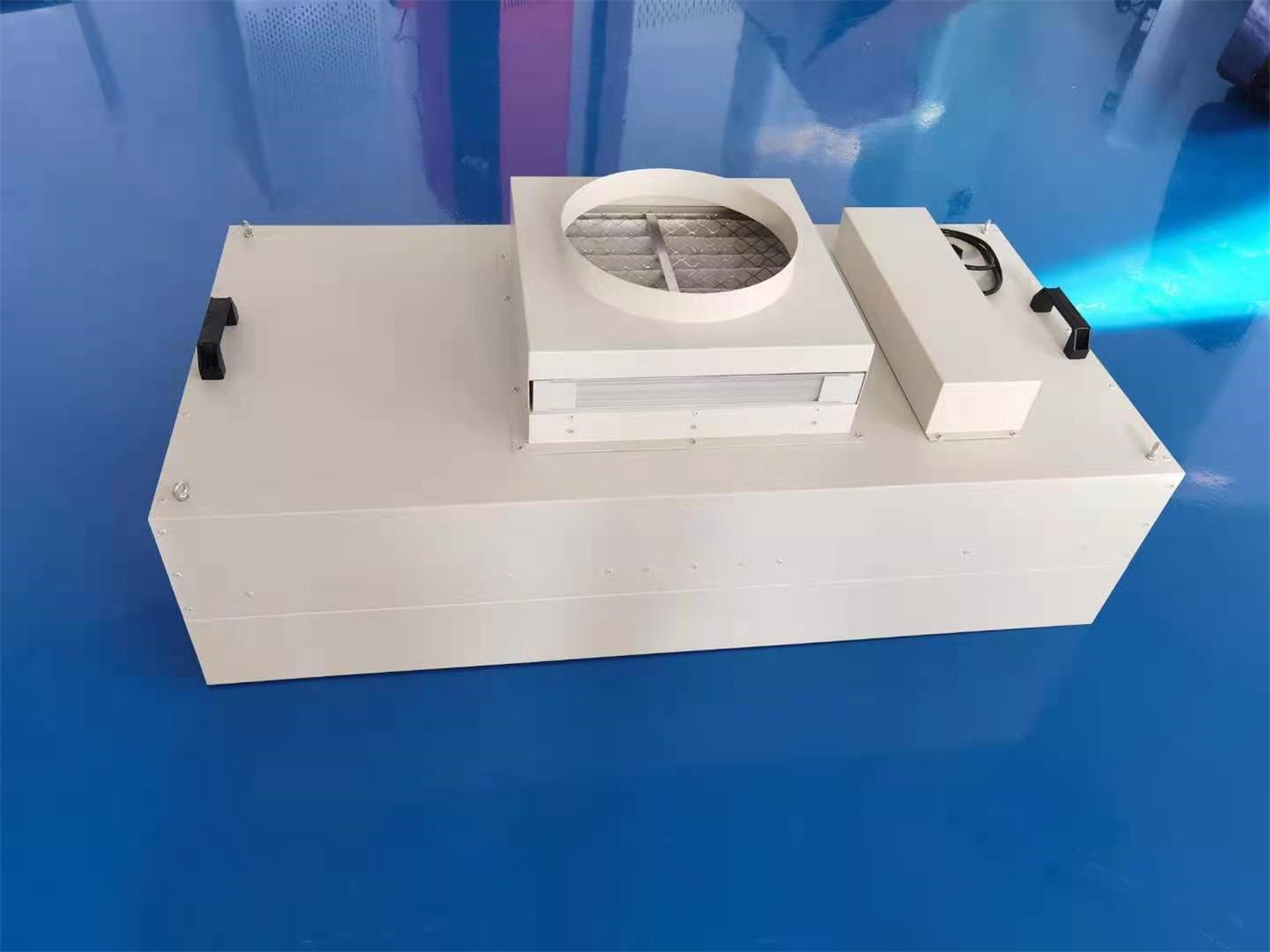

FFU structure

1. Appearance

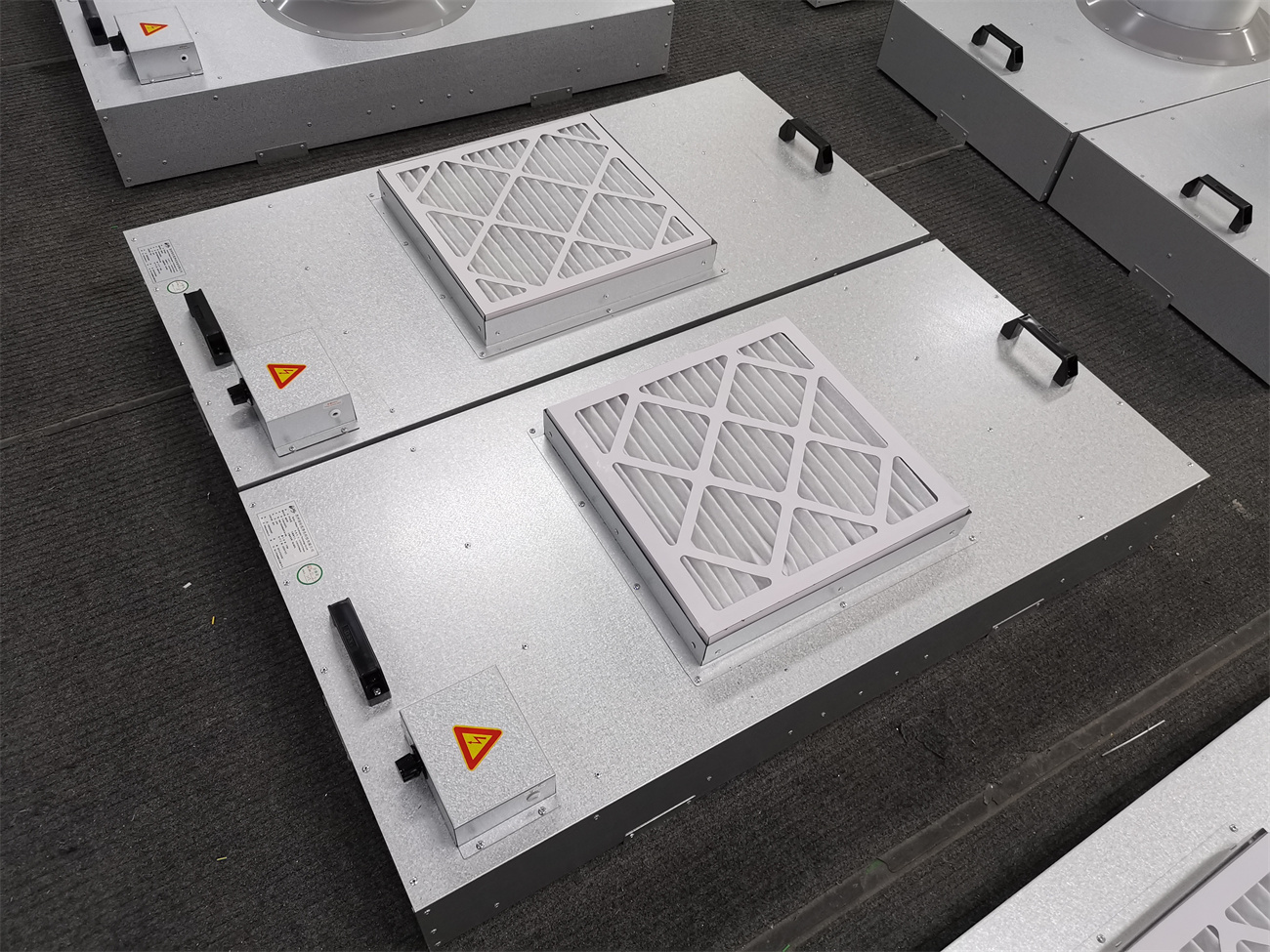

Split type: makes the replacement of filter convenient and reduces labor intensity during installation.

Integrated type: increases the sealing performance of the FFU, effectively preventing leakage; Beneficial for reducing noise and vibration.

2. Basic structure of FFU case

FFU mainly consists of 5 parts:

1) Case

The material commonly used is aluminum-coated galvanized steel plate, stainless steel and powder coated steel plate. The first function is to support fan and air guide ring, and the second function is to support air guide plate;

2) Air guide plate

A balance device for air flow, built-in inside surrounding case under fan;

3) Fan

There are 2 types of fans including AC and EC fan;

4) Filter

Prefilter: used to filter large dust particles, composed of non-woven fabric filter material and paperboard filter frame; High-efficiency filter: HEPA/ULPA ; Example: H14, with filter efficiency of 99.999%@ 0.3um; Chemical Filter: For removing ammonia, boron, organic gases, etc., it is generally installed at air inlet using the same installation method as the prefilter.

5) Control components

For AC FFU, 3 speed manual switch is commonly used; For EC FFU,the control chip is embedded inside the motor, and remote control is achieved through specialized control software, computers, control gateways, and network circuits.

FFU basic parameters and selection

The general specifications are as follows:

Size: match with ceiling size;

Material: Environmental requirements, cost considerations;

Surface air velocity: 0.35-0.45m/s, with significant differences in power consumption;

Static pressure: overcome air resistance requirements;

Filter: according to cleanliness level requirements;

Motor: power characteristics, power, bearing life;

Noise: meet with noise requirements of clean room.

1. Basic parameters

1) Surface air velocity

Generally between 0 and 0.6m/s, for 3 speed regulation, the corresponding air velocity for each gear is approximately 0.36-0.45-0.54m/s while for a stepless speed regulation, it is approximately 0 to 0.6m/s.

2) Power consumption

The AC system is generally between 100-300 watts; The EC system is between 50-220 watts. The power consumption of EC system is 30-50% lower than AC system.

3) Uniformity of air velocity

Refers to the uniformity of FFU surface air velocity, which is particularly strict in high-level clean rooms, otherwise it can easily cause turbulence. The excellent design and process level of fan, filter, and diffuser determine the quality of this parameter. When testing this parameter, 6-12 points are evenly selected based on the size of the FFU air outlet surface to test air velocity. The maximum and minimum values should not exceed ± 20% compared to average value.

4) External static pressure

Also known as residual pressure, this parameter is related to the service life of FFU and is closely related to the fan. Generally, it is required that the external static pressure of the fan should not be less than 90Pa when surface air velocity is 0.45m/s.

5) Total static pressure

Also known as total pressure, which refers to the static pressure value that FFU can provide at maximum power and zero air velocity. Generally, the static pressure value of AC FFU is around 300Pa, and that of EC FFU is between 500-800Pa. Under a certain air velocity, it can be calculated as follows: total static pressure (TSP)= external static pressure (ESP, the static pressure provided by FFU to overcome the resistance of external pipelines and return air ducts)+filter pressure loss (the filter resistance value at this air velocity).

6)Noise

The general noise level is between 42 and 56 dBA. When using it, attention should be paid to the noise level at surface air velocity of 0.45m/s and external static pressure of 100Pa. For FFUs with the same size and specification, EC FFU is 1-2 dBA lower than the AC FFU.

7) Vibration rate: generally less than 1.0mm/s.

8) Basic dimensions of FFU

| Basic Module(Center line distance in between ceiling keels) | FFU Overall Size(mm) | Filter Size(mm) | |

| Metric Unit(mm) | English Unit(ft) | ||

| 1200*1200 | 4*4 | 1175*1175 | 1170*1170 |

| 1200*900 | 4*3 | 1175*875 | 1170*870 |

| 1200*600 | 4*2 | 1175*575 | 1170*570 |

| 900*600 | 3*2 | 875*575 | 870*570 |

| 600*600 | 2*2 | 575*575 | 570*570 |

Remarks:

①The above width and length dimensions have been widely used by various manufacturers both domestically and internationally, and the thickness varies from manufacturer to manufacturer.

②In addition to above basic dimensions mentioned, non-standard specifications can be customized, but it is not as appropriate to use standard specifications in terms of delivery time or price.

9) HEPA/ULPA Filter Models

| EU EN1822 |

USA IEST |

ISO14644 |

FS209E |

|

H13 |

99.99%@0.3um |

ISO 5 or below | Class 100 or below |

| H14 | 99.999%@0.3um | ISO 5-6 | Class 100-1000 |

| U15 | 99.9995%@0.3um | ISO 4-5 | Class 10-100 |

|

U16 |

99.99995%@0.3um |

ISO 4 | Class 10 |

|

U17 |

99.999995%@0.3um |

ISO 1-3 | Class 1 |

Remarks:

①The level of clean room is related to two factors: filter efficiency and air change (supply air volume); Using high-efficiency filters cannot achieve the relevant level even if air volume is too low.

②The above EN1822 is currently a commonly used standard in Europe and America.

2. FFU Selection

FFU fans can be selected from AC fan and EC fan.

1) Selection of AC fan

AC FFU uses manual switch control, as its initial investment is relatively small; Commonly used in clean rooms with less than 200 FFUs.

2) Selection of EC fan

EC FFU is suitable for clean rooms with a large number of FFUs. It uses computer software to intelligently control the operation status and faults of each FFU, saving maintenance costs. Each software set can control multiple main gateways, and each gateway can control 7935 FFUs.

EC FFU can save more than 30% energy compared to AC FFU, which is a significant annual energy savings for a large number of FFU systems. At the same time, EC FFU also has the characteristic of low noise.

Post time: May-18-2023