Clean room construction should be carried out after the acceptance of the main structure, roof waterproofing project and outer enclosure structure.

Clean room construction should develop clear construction collaboration plans and construction procedures with other types of work.

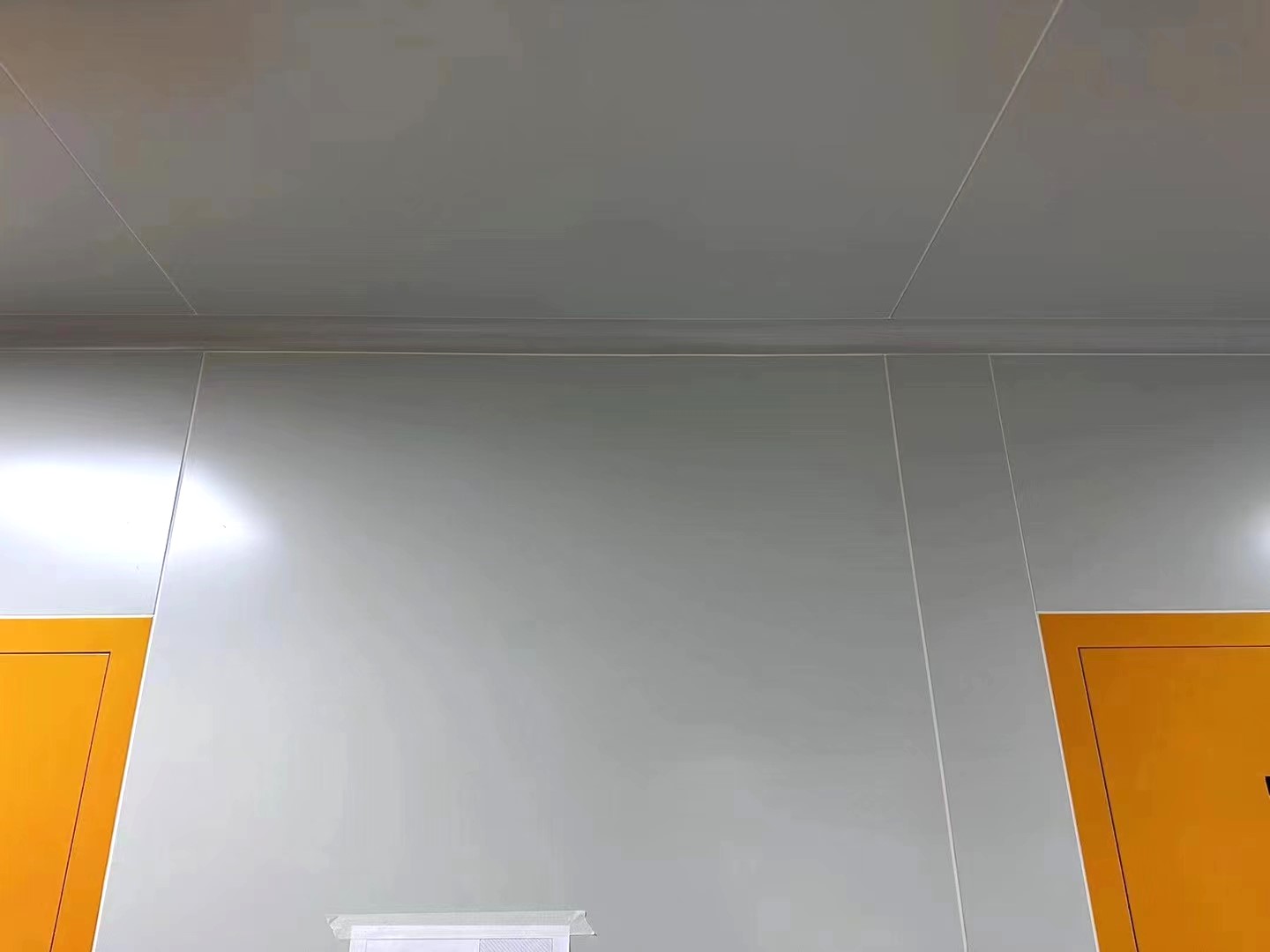

In addition to meeting the requirements of heat insulation, sound insulation, anti-vibration, anti-insect, anti-corrosion, fire prevention, anti-static and other requirements, the building decoration materials of the clean room should also ensure the air tightness of the clean room and ensure that the decorative surface does not produce dust, does not absorb dust, do not accumulate dust and should be easy to clean.

Wood and gypsum board should not be used as surface decoration materials in clean room.

Clean room construction should implement closed cleaning management at construction site. When dust operations are carried out in clean construction areas, measures should be taken to effectively prevent the spread of dust.

The ambient temperature of the clean room construction site should not be lower than 5℃. When constructing at ambient temperatures below 5°C, measures should be taken to ensure construction quality. For decoration projects with special requirements, construction should be carried out according to the temperature required by the design.

Ground construction should comply with the following regulations:

1. A moisture-proof layer should be installed on the ground floor of the building.

2. When the old floor is made of paint, resin or PVC, the original floor materials should be removed, cleaned, polished, and then leveled. The concrete strength grade should not be less than C25.

3. The ground must be made of corrosion-resistant, wear-resistant and anti-static materials.

4. The ground should be flat.

Post time: Mar-08-2024