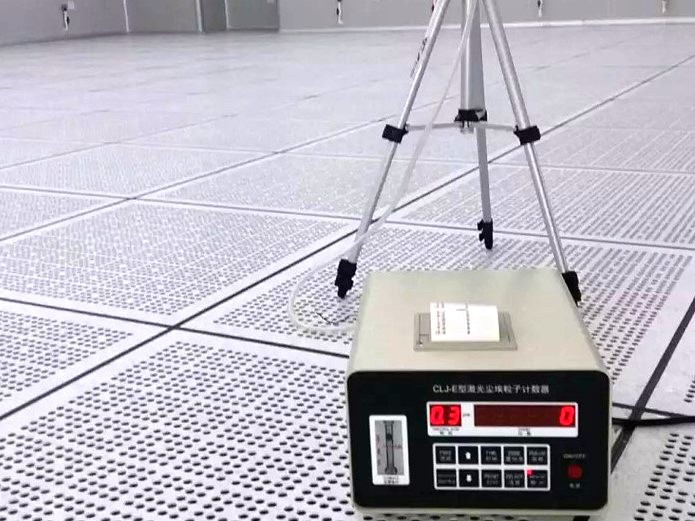

In order to meet GMP regulations, clean rooms used for pharmaceutical production need to meet the corresponding grade requirements. Therefore, these aseptic production environments require strict monitoring to ensure the controllability of the production process. Environments that require key monitoring generally install a set of dust particle monitoring system, which includes: control interface, control equipment, particle counter, air pipe, vacuum system and software, etc.

A laser dust particle counter for continuous measurement is installed in each key area, and each area is continuously monitored and sampled through the workstation computer excitation command, and the monitored data is transmitted to the workstation computer, and the computer can display and issue a report after receiving the data to the operator. The selection of the location and quantity of online dynamic monitoring of dust particles should be based on risk assessment research, requiring coverage of all key areas.

The determination of the sampling point of the laser dust particle counter refers to the following six principles:

1. ISO14644-1 specification: For a unidirectional flow clean room, the sampling port should face the airflow direction; for a non-unidirectional flow clean room, the sampling port should face upward, and the sampling speed at the sampling port should be as close as possible to the indoor airflow speed ;

2. GMP principle: the sampling head should be installed close to the working height and the place where the product is exposed;

3. The sampling location will not affect the normal operation of the production equipment, and will not affect the normal operation of the personnel in the production process, so as to avoid affecting the logistics channel;

4. The sampling position will not cause large counting errors due to particles or droplets generated by the product itself, causing the measurement data to exceed the limit value, and will not cause damage to the particle sensor;

5. The sampling position is selected above the horizontal plane of the key point, and the distance from the key point should not exceed 30cm. If there is liquid splash or overflow in a special position, resulting in the measurement data results exceeding the regional standard of this level under simulated production conditions, the distance in the vertical direction can be limited Appropriately relax, but should not exceed 50cm;

6. Try to avoid placing the sampling position directly above the passage of the container, so as not to cause insufficient air above the container and turbulence.

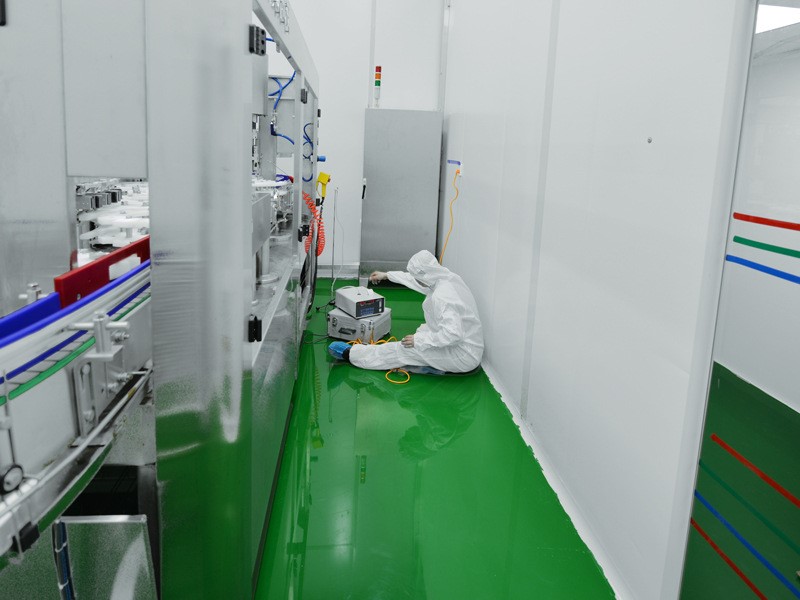

After all candidate points are determined, under the conditions of the simulated production environment, use a laser dust particle counter with a sampling flow rate of 100L per minute to sample each candidate point in each key area for 10 minutes, and analyze the dust of all points particle sampling data logging.

The sampling results of multiple candidate points in the same area are compared and analyzed to find out the high-risk monitoring point, so as to determine that this point is a suitable dust particle monitoring point sampling head installation position.

Post time: Aug-09-2023