During daily supervision process, it was found that the current construction of clean room in some enterprises is not standardized enough. Based on various problems that arise in production and supervision processes of many medical device manufacturers, the following requirements for clean room construction are proposed, especially for sterile medical device industry.

1. Site selection requirements

(1). When selecting a factory site, you should consider that the natural environment and sanitary conditions around the location are good, at least there are no sources of air or water pollution, and it should be far away from main traffic roads, cargo yards, etc.

(2). Environmental requirements of the factory area: The ground and roads in factory area should be smooth and dust-free. It is advisable to reduce the area of exposed soil through greening or other measures or to take measures to control dust. Garbage, idle items, etc. should not be stored in open. In short, the environment of the factory should not cause pollution to the production of sterile medical devices.

(3). The overall layout of the factory area must be reasonable: it must not have any adverse impact on the production area of sterile medical devices, especially clean area.

2. Clean room (area) layout requirements

The following aspects should be paid attention to in clean room design.

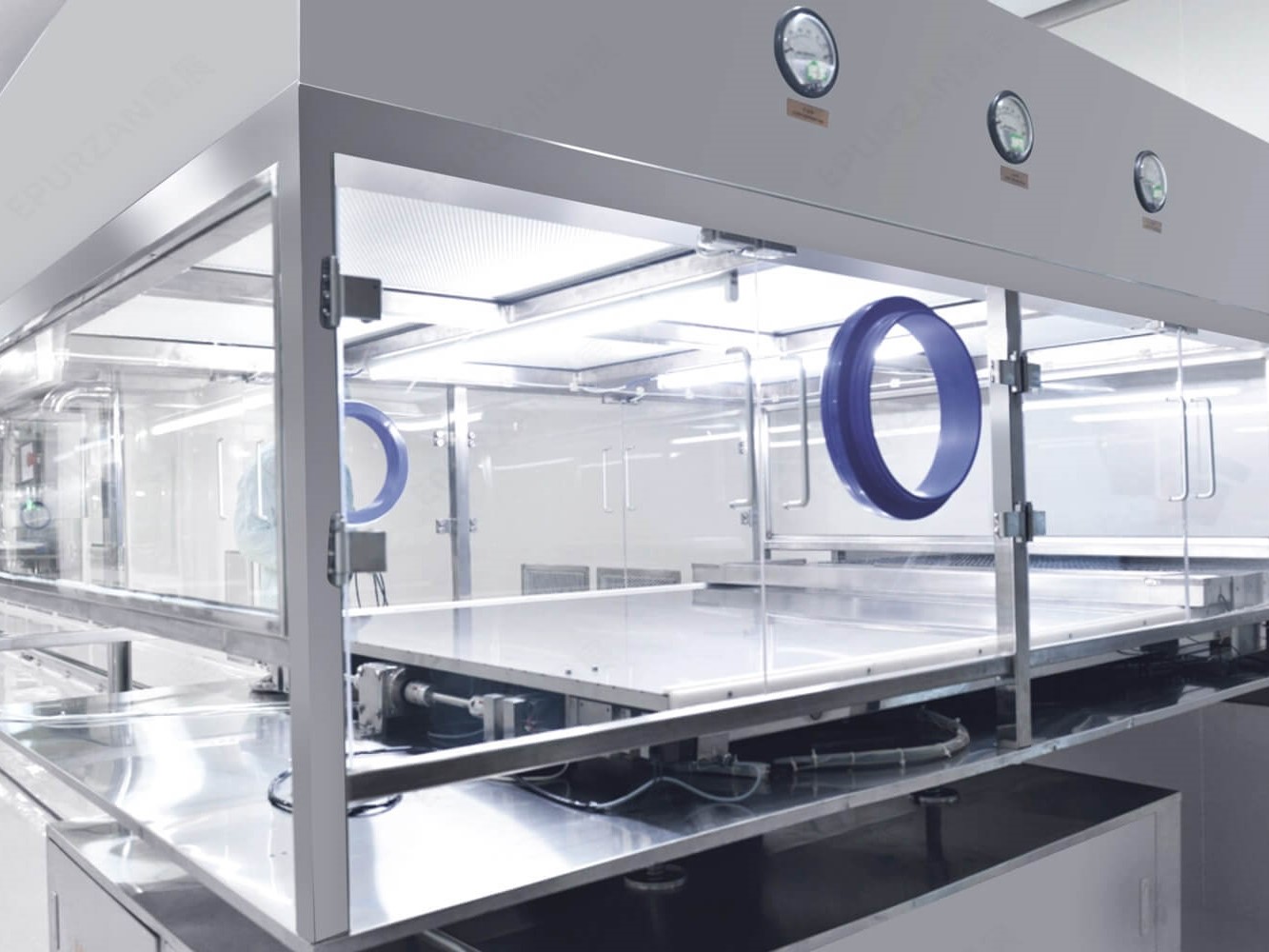

(1). Arrange according to the production process flow. The process should be as short as possible to reduce the rate of interactions between people and animals, and ensure a reasonable flow of people and logistics. It must be equipped with a personnel clean room (coat storage room, washroom, clean room clothes wearing room and buffer room), material clean room (outsourcing room, buffer room and pass box). In addition to the rooms required by product processes, it should also be equipped with It is equipped with a sanitary ware room, laundry room, temporary storage room, work station equipment cleaning room, etc. Each room is independent of each other. The area of the clean room should be consistent with the production scale while ensuring the basic requirements.

(2). According to the air cleanliness level, it can be written according to the direction of personnel flow, from low to high; the workshop is from inside to outside, from high to low.

3. No cross-contamination occurs within the same clean room (area) or between adjacent clean rooms.

① The production process and raw materials will not affect product quality;

② There are airlocks or anti-pollution measures between clean rooms (areas) of different levels, and materials are transferred through pass box.

4. The amount of fresh air in clean room should take the following maximum value: The amount of fresh air required to compensate for the indoor exhaust volume and maintain positive indoor pressure; The amount of fresh air when no one is in clean room should be less than 40 m3/h.

5. The per capital area of the clean room should be no less than 4 square meters (excluding corridors, equipment and other items) to ensure a safe operating area.

6. In vitro diagnostic reagents should comply with the requirements of the "Implementation Rules for the Production of In Vitro Diagnostic Reagents (Trial)". Among them, the processing operations of negative and positive serum, plasmids or blood products should be carried out in an environment of at least class 10000, maintaining relative negative pressure with adjacent areas or in compliance with protection requirements.

7. The direction of the return air, supply air and water pipes should be marked.

8. Temperature and humidity requirements

(1). Compatible with production process requirements.

(2). When there are no special requirements for the production process, the temperature of the clean room (area) with an air cleanliness level of class 100000 or 10000 shall be 20℃~24℃, and the relative humidity shall be 45%~65%; the air cleanliness level shall be class 100000 or 300000. The temperature of a class 10,000 clean room (area) should be 18°C to 26°C, and the relative humidity should be 45% to 65%. If there are special requirements, they should be determined according to the process requirements.

(3). The temperature of the personnel clean room should be 16°C ~ 20°C in winter and 26°C ~ 30°C in summer.

(4). Commonly used monitoring equipment

Anemometer, dust particle counter, temperature and humidity meter, differential pressure meter, etc.

(5). Requirements for sterile testing rooms

The clean room must be equipped with a sterility testing room (separate from production area) with an independent purification air-conditioning system, which is required to be a local class 100 under class 10000 conditions. The sterility testing room should include: personnel clean room (coat storage room, washroom, clean room clothes wearing room and buffer room), material clean room (buffer room or pass box), sterility inspection room, and positive control room.

(6). Environmental testing reports from third-party testing agencies

Provide an environmental testing report from a qualified third-party testing agency within one year. The testing report must be accompanied by a floor plan indicating the area of each room.

① There are currently six testing items: temperature, humidity, pressure difference, number of air changes, dust count, and sedimentation bacteria.

② The parts tested are: Production workshop: personnel clean room; material clean room; buffer area; rooms required for product process; work station equipment cleaning room, sanitary ware room, laundry room, temporary storage room, etc. Sterility testing room.

(7). Catalog of medical device products that require clean room production. Sterile medical devices or single-packaged factory accessories that are implanted and inserted into blood vessels and require subsequent processing (such as filling and sealing, etc.) in a local class 100 clean area under class 10000. The processing of components, final cleaning, assembly, initial packaging and sealing and other production areas should have a cleanliness level of no less than class 10000.

Example

① Implantation of blood vessels: such as vascular stents, heart valves, artificial blood vessels, etc.

② Interventional blood vessels: various intravascular catheters, etc. Such as central venous catheters, stent delivery systems, etc.

③ The processing, final cleaning and assembly of sterile medical devices or single-packaged factory accessories that are implanted in human tissue and directly or indirectly connected to the blood, bone marrow cavity or unnatural orifice (without cleaning). The initial packaging and sealing and other production areas should have a cleanliness level of no less than class 100000.

④ Devices implanted in human tissue: pacemakers, subcutaneous implantable drug delivery devices, artificial breasts, etc.

⑤ Direct contact with blood: plasma separator, blood filter, surgical gloves, etc.

⑥ Devices that are in indirect contact with blood: infusion sets, blood transfusion sets, intravenous needles, vacuum blood collection tubes, etc.

⑦ Bone contact devices: intraosseous devices, artificial bones, etc.

⑧ The processing, final fine cleaning, assembly, initial packaging and sealing of sterile medical devices or single-packaged factory (not cleaned) parts that come into contact with damaged surfaces and mucous membranes of the human body should be carried out in a clean room of no less than class 300000 (area).

Example

① Contact with the injured surface: burn or wound dressings, medical absorbent cotton, absorbent gauze, disposable sterile surgical supplies such as surgical pads, surgical gowns, medical masks, etc.

② Contact with mucous membrane: sterile urinary catheter, tracheal intubation, intrauterine device, human lubricant, etc.

③ For primary packaging materials that are in direct contact with the surfaces of sterile medical devices and are used without cleaning, the cleanliness level of the production environment should be set in accordance with the same principles as the cleanliness level of the product production environment to ensure that the quality of the primary packaging materials is to meet the requirements for packaged sterile medical devices, if the initial packaging material does not directly contact the surface of the sterile medical device, it should be produced in a clean room (area) with an area of no less than class 300000.

Example

① Direct contact: such as initial packaging materials for applicators, artificial breasts, catheters, etc.

② No direct contact: such as initial packaging materials for infusion sets, blood transfusion sets, syringes, etc.

③ Sterile medical devices (including medical materials) that are required or processed using aseptic operation techniques should be produced in local class 100 clean rooms (areas) under class 10000.

Example

① Such as the filling of anticoagulants and maintenance solutions in the production of blood bags, and the aseptic preparation and filling of liquid products.

② Press and hold the vascular stent and apply medicine.

Remark:

① Sterile medical devices include medical devices that are free of any viable microorganisms through terminal sterilization or aseptic processing techniques. Production technology that minimizes contamination should be used in the production of sterile medical devices to ensure that the medical devices are not contaminated or can effectively eliminate contamination.

② Sterility: The state in which a product is free of viable microorganisms.

③ Sterilization: A validated process used to render a product free of any form of viable microorganisms.

④ Aseptic processing: Aseptic preparation of products and aseptic filling of products in a controlled environment. The environment's air supply, materials, equipment and personnel are controlled so that microbial and particulate contamination is controlled to acceptable levels.

Sterile medical equipment: refers to any medical equipment marked "sterile".

⑤ The clean room must include a sanitary ware room, laundry room, temporary storage room, work station equipment cleaning room, etc.

Products produced under purified conditions refer to products that require sterility or sterilization for final use.

Post time: Jan-30-2024