1.Introduction

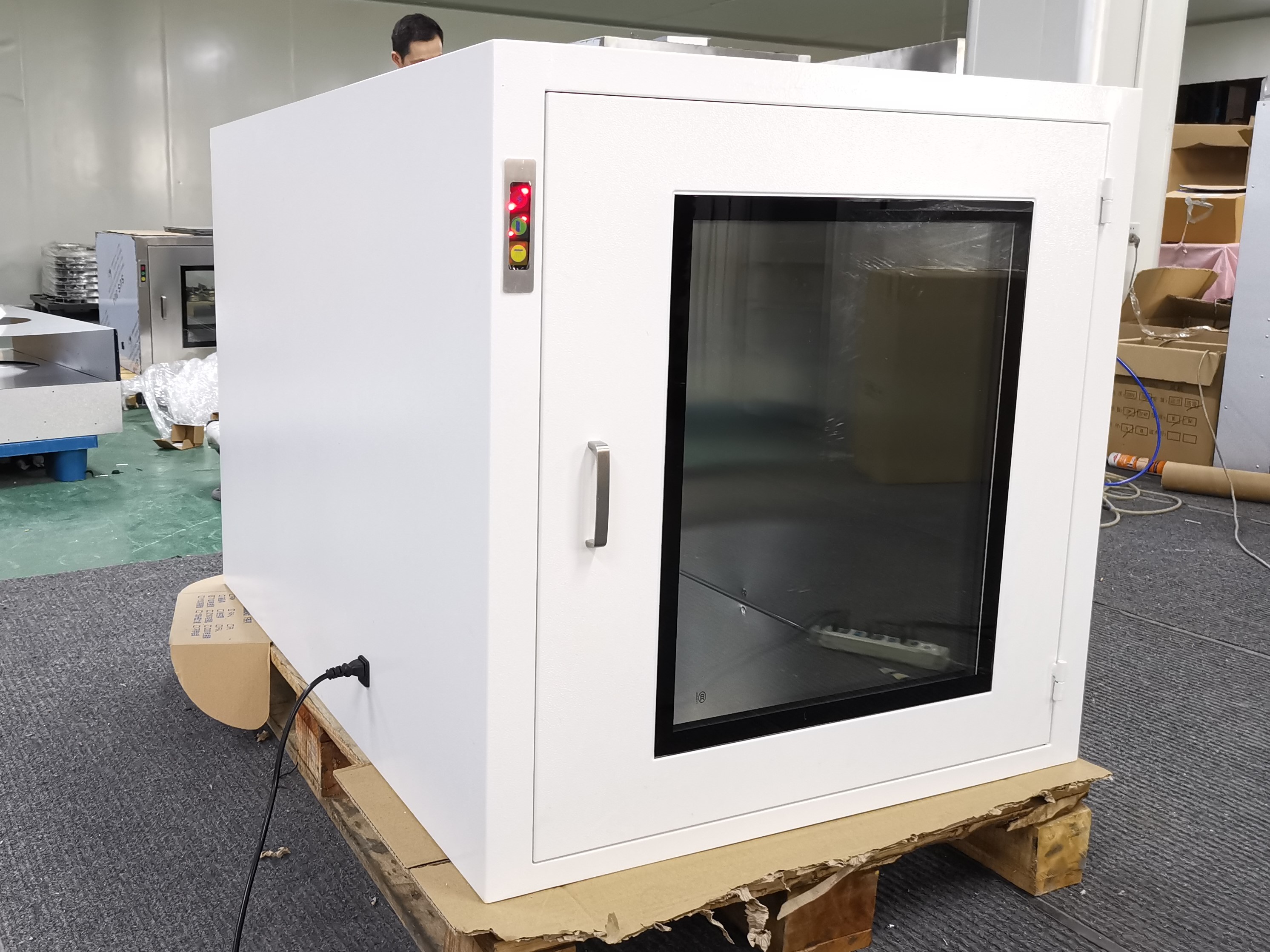

Pass box, as an auxiliary equipment in clean room, is mainly used to transfer small items between clean area and clean area, as well as between non clean area and clean area, in order to reduce the times of door openings in clean room and minimize pollution in clean area. The pass box is made of full stainless steel plate or external power coated steel plate and internal stainless steel plate, which is flat and smooth. The two doors are interlocked with each other, effectively preventing cross contamination, equipped with electronic or mechanical interlock, and equipped with UV lamp or lighting lamp. Pass box is widely used in micro technology, biological laboratories, pharmaceutical factories, hospitals, food processing industries, LCD, electronic factories, and other places that require air purification.

2.Classification

Pass box can be divided into static pass box, dynamic pass box and air shower pass box according to their working principles. Various models of pass boxes can be made according to actual requirements. Optional accessories: interphone, UV lamp and other related functional accessories.

3.Characteristics

①The working surface of short-distance pass box is made of stainless steel plate, which is flat, smooth, and wear-resistant.

②The working surface of long-distance pass box adopts a roller conveyor, making it easy and convenient to transfer items.

③Both sides of the doors are equipped with mechanical interlock or electronic interlock to ensure both sides of the doors cannot be opened at the same time.

④We can customize various non-standard sizes and floor mounted pass box according to customer needs.

⑤The air velocity at air outlet can reach over 20 m/s.

⑥Adopting a high-efficiency filter with a partition, the filtration efficiency is 99.99%, ensuring the cleanliness level.

⑦Using EVA sealing material, with high sealing performance.

⑧Match with interphone available.

4.Working Principle

①Mechanical interlock: Internal interlock is achieved through mechanical means. When one door is opened, the other door cannot be opened and must be closed before opening the other door.

②Electronic interlock: Internal interlock is achieved by using integrated circuits, electromagnetic locks, control panels, indicator lights, etc. When one door is opened, the opening indicator light of the other door does not light up, indicating that the door cannot be opened, and the electromagnetic lock operates to achieve interlocking. When the door is closed, the electromagnetic lock of the other door starts to work, and the indicator light will light up, indicating that the other door can be opened.

5.Usage Method

The pass box should be managed according to the higher cleanliness area connected to it. For example, the pass box, which is connected in between spray code room and filling room, should be managed according to the requirements of the filling room. After work, the operator in the clean area is responsible for wiping the internal surfaces of the pass box and turning on the UV lamp for 30 minutes.

①Materials entering and exiting the clean area must be strictly separated from the pedestrian passage and accessed through a dedicated passage for materials in the production workshop.

②When the 2 materials enter, the process leader of the preparation team organizes personnel to unpack or clean the appearance of the raw and auxiliary materials, and then sends them to the temporary storage room of the workshop raw and auxiliary materials through the pass box; The inner packaging materials are removed from the outer temporary storage room and sent to the inner packaging room through the pass box. The workshop manager and the person in charge of the preparation and inner packaging processes handle material handover.

③When passing through the pass box, the regulations of "one opening and one closing" must be strictly followed for the inner and outer doors of the pass box, and two doors cannot be opened at the same time. Open the outer door to put the materials in, close the door first, then open the inner door to take out the materials, close the door, and cycle like this.

④When delivering materials from the clean area, the materials should first be transported to the relevant material intermediate station and moved out of the clean area according to the reverse procedure when the materials enter.

⑤All semi-finished products transported from the clean area need to be transported from the pass box to the external temporary storage room, and then transported through the logistics channel to the external packaging room.

⑥Materials and waste that are prone to pollution should be transported from their dedicated pass box to non clean areas.

⑦After the entry and exit of materials, the site of each clean room or intermediate station and the hygiene of the pass box should be cleaned in a timely manner. The internal and external passage doors of the pass box should be closed, and cleaning and disinfection work should be done well.

6.Precautions

①The pass box is suitable for general transportation, and during transportation, it should be protected from rain and snow to prevent damage and rust.

②The pass box should be stored in a warehouse with a temperature of -10 ℃~+40 ℃, a relative humidity of not more than 80%, and no corrosive gases such as acid or alkali.

③When unpacking, civilized operation should be carried out, and there should be no rough or barbaric operations to avoid personal injury.

④After unpacking, please firstly confirm whether this product is the ordered product, and then carefully check the contents of the packing list for any missing parts and whether there are any damages caused by transportation to each component.

7.Operating Specifications

①Wipe the item to be transferred with 0.5% peracetic acid or 5% iodophor solution.

②Open the door outside pass box, quickly place the items to be transferred, disinfect the item with 0.5% peracetic acid spray, and close the door outside the pass box.

③Turn on UV lamp inside pass box, and irradiate the item to be transferred with UV lamp for no less than 15 minutes.

④Notify the laboratory or staff within the barrier system to open the door inside pass box and take out the item.

⑤Close the item.

Post time: May-16-2023