In 2022, one of our Ukraine client approached us with the request of creating several ISO 7 and ISO 8 laboratory clean rooms to grow plants within an existing building that comply with ISO 14644. We have been entrusted with both complete design and manufacturing of the project. Recently all items have been arrived on site and are ready for clean room installation. Therefore, now we would like to make a summary of this project.

Cost of a cleanroom is not only extremely investment intensive, but depending on the number of required air exchanges and filtration efficiency. Operation can be extremely costly, as appropriate air quality can only be maintained with constant operation. Not to mention energy-efficient operation and continuous adherence to cleanroom standards that make a cleanroom one of the most important infrastructures for manufacturing technology and laboratories.

Design and Preparation Phase

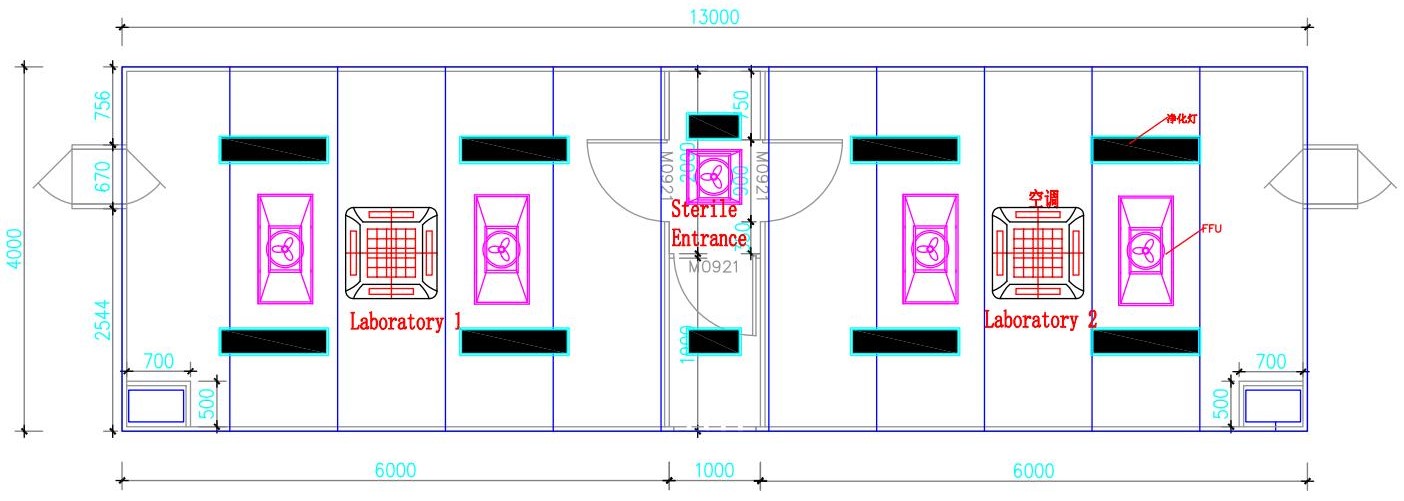

Since we specialize in custom-built clean rooms for various industrial needs, we gladly accepted the challenge with the hope of being able to provide a simple, cost-effective solution that can even exceed expectations. During the design phase, we created detailed sketches of the clean space that were to include the following rooms:

List of Clean Rooms

|

Room Name |

Room Size |

Ceiling Height |

ISO Class |

Air Exchange |

|

Laboratory 1 |

L6*W4m |

3m |

ISO 7 |

25 times/h |

|

Laboratory 2 |

L6*W4m |

3m |

ISO 7 |

25 times/h |

|

Sterile Entrance |

L1*W2m |

3m |

ISO 8 |

20 times/h |

Standard Scenario:Design with Air Handling Unit(AHU)

At first, we drafted a traditional clean room with constant temperature and humidity AHU and made calculations for the entire cost. In addition to the design and manufacturing of the clean rooms, the initial offer and the preliminary plans included an air handling unit with 15-20% than required higher air supply. The original plans have been made in accordance with laminar flow rules with supply and return manifolds and integrated H14 HEPA filters.

The total clean space to be constructed made up about 50 m2, which essentially meant several small clean rooms.

More Cost When Designed with AHU

Typical investment cost for complete cleanrooms varies depending on:

·Required level of cleanliness of the clean room;

·Technology used;

·Size of the rooms;

·Division of the clean space.

It’s important to note that in order to filter and exchange the air properly, much higher power requirements are needed than for instance in a common office environment. Not to mention that hermetically sealed clean rooms also require fresh air supply.

In this case, the clean space was strongly divided on a very small floor area, where 3 smaller rooms (Laboratory #1, Laboratory #2, Sterile Entrance) had an ISO 7 and ISO 8 cleanliness requirement, resulting in a significant increase in initial investment cost. Understandably, the high investment cost also shook the investor, as the budget for this project was limited.

Redesign with A Cost-effective FFU Solution

At the request of the investor, we started exploring cost reduction options. The layout of the clean room as well as the number of doors and pass boxes were given, no extra savings could be achieved here. In contrast, redesigning the air supply system seemed an obvious solution.

Therefore, ceilings of the rooms were redesigned as duplicates, the required air volume was calculated and compared with the height of the available room. Fortunately, there was enough space to increase the height. The idea was to place FFUs through the ceilings, and from there supply clean air to the clean rooms via HEPA filters with the help of an FFU system (fan filter units). Return air is recirculated with the help of gravity through air ducts on sidewalls, which are mounted into the walls, so that no space is lost.

Unlike AHU, FFUs allow air to flow into each zone to meet the requirements of that specific zone.

During redesign, we included ceiling-mounted air conditioner through the ceilings with adequate capacity, which can both heat and cool the space. FFUs have been arranged to provide optimal air flow within the space.

Cost Saving Achieved

The redesign resulted in significant savings as the new design allowed for the exclusion of several costly elements such as

·AHU;

·Complete duct system with control elements;

·Motorized valves.

The new design consists of a very simple system that not only significantly reduces investment costs, but also leads to lower operating costs than an AHU system.

In contrast to the original design, the redesigned system fit into the investor’s budget, so we contracted for the project.

Conclusion

In the light of the achieved results, it can be stated that clean room implementations with FFU systems complying with ISO14644 or GMP standards can result in significant cost reduction. Cost advantage can be achieved regarding both the investment and operating costs. The FFU system can also be controlled very easily, thus, if necessary, the clean room can be placed at rest during the out-of-shift periods.

Post time: Apr-28-2023