Hepa filters are currently popular clean equipment and an indispensable part of industrial environmental protection. As a new type of clean equipment, its characteristic is that it can capture fine particles ranging from 0.1 to 0.5um, and even has a good filtering effect on other pollutants, thereby ensuring the improvement of air quality and providing an appropriate environment for people's lives and industrial production.

The filtering layer of hepa filters has four main functions for capturing particles:

1. Interception effect: When a particle of a certain size moves near the surface of a fiber, the distance from the centerline to the surface of the fiber is less than the particle radius, and the particle will be intercepted by the filter material fiber and deposited.

2. Inertia effect: When particles have a large mass or velocity, they collide with the surface of the fiber due to inertia and deposit.

3. Electrostatic effect: Both fibers and particles may carry charges, creating an electrostatic effect that attracts particles and adsorbs them.

4. Diffusion motion: small particle size example Brownian motion is strong and easy to collide with the fiber surface and deposit.

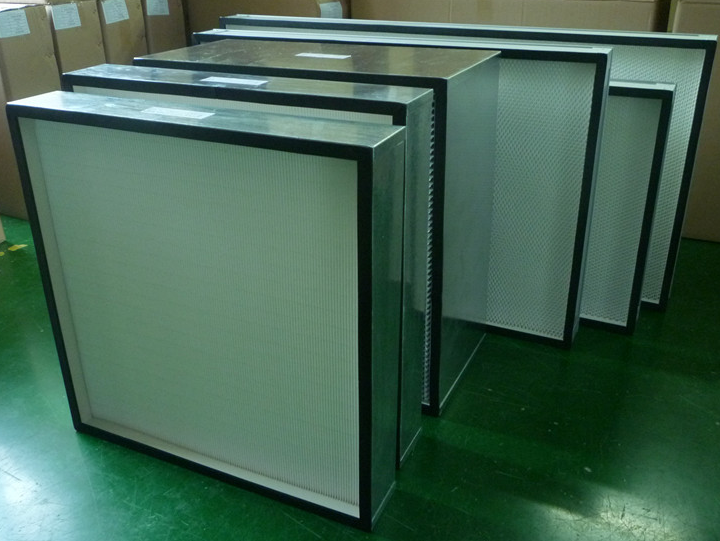

Mini pleat hepa filter

There are many types of hepa filters, and different hepa filters have different usage effects. Among them, mini pleat hepa filters are commonly used filtration equipment, usually serving as the end of the filtration equipment system for efficient and precise filtration. However, the major feature of hepa filters without partitions is the absence of partition design, where the filter paper is directly folded and formed, which is the opposite of filters with partitions, but can achieve ideal filtration results. The difference between mini and pleat hepa filters: Why is a design without partitions called a deep pleat hepa filter? Its great feature is the absence of partitions. When designing, there were two types of filters, one with partitions and the other without partitions. However, it was found that both types had similar filtration effects and could purify different environments. Therefore, mini pleat hepa filters were widely used.

The design of a mini pleat hepa filter not only distinguishes other filtering equipment, but also is designed according to the usage requirements, which can achieve effects that other equipment cannot achieve. Although filters have good filtering effects, there are not many equipment that can meet the purification and filtration needs of some places, so the production of mini pleat hepa filters is very necessary. The mini pleat hepa filter can filter small suspended particles and purify air pollution as much as possible. It is generally used at the end of equipment system devices to meet people's purification needs through efficient purification. The above is the difference between mini pleat hepa filters. In fact, when designing filters, the focus is not only on extending their performance, but also on meeting usage needs. Therefore, a mini pleat hepa filter was ultimately designed. The use of mini pleat hepa filters is very common and has become a filter equipment in many places.

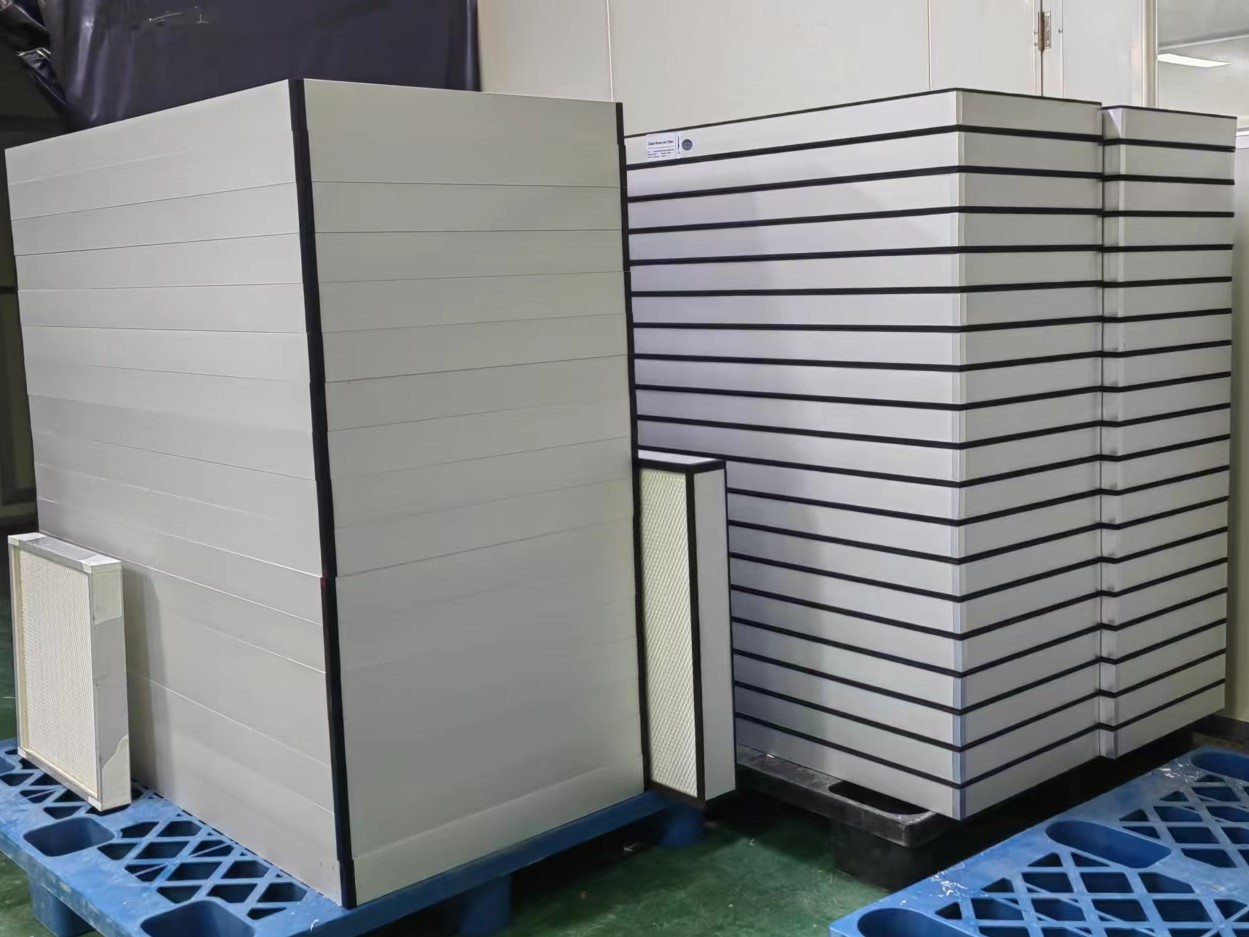

Deep pleat hepa filter

As the amount of filtered particles increases, the filtration efficiency of the filter layer will decrease, while the resistance will increase. When it reaches a certain value, it should be replaced in a timely manner to ensure purification cleanliness. The deep pleat hepa filter uses Hot-melt adhesive instead of aluminum foil with separator filter to separate the filter material. Due to the absence of partitions, a 50mm thick mini pleat hepa filter can achieve the performance of a 150mm thick deep pleat hepa filter. It can meet the stringent demands of various space, weight, and energy consumption for air purification today.

In air filters, the main functions that play are the filter element structure and filter material, which have filtering performance and constantly affect the performance of the air filter. From a certain perspective, materials are the key factor determining the performance of filters. For example, filters with activated carbon as the filter core and filters with glass fiber filter paper as the main filter core will have very significant differences in performance.

Relatively speaking, some materials with smaller structural diameters have better filtration performance, such as glass fiber paper structures, which are composed of extremely fine glass fibers and adopt special processes to form a structure similar to multi-layer weaving, which can greatly improve adsorption efficiency. Therefore, such a precise fiberglass paper structure is generally used as the filter element for hepa filters, while for the filter element structure of primary filters, filter cotton structures with larger diameters and easier materials are generally used.

Post time: Jul-06-2023