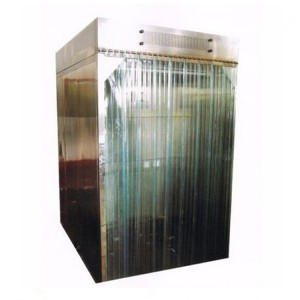

CE Standard Pharmaceutical Stainless Steel Weighing Booth

Product Description

Weighing booth is also called sampling booth and dispensing booth, which use vertical single-direction laminar flow. Return air is prefiltered by prefilter first to sort out big particle in airflow. Then air is filtered by medium filter for the second time in order to protect HEPA filter. Finally, clean air can enter working area via HEPA filter under the pressure of centrifugal fan to achieve high cleanliness requirement. Clean air is delivered to supply fan box, 90% air become uniform vertical supply air via supply air screen board while 10% air is exhausted out via airflow adjusting board. All air is handled by HEPA filter, so all supply and exhaust air don’t carry remaining dust to avoid twice contamination. Due to stable single-direction airflow in working area, dust particle is handled by prefilter and medium filter. The unit has 10% exhaust air that cause negative pressure compare to outside environment, which ensure dust in working area not to spread to outside to some extent and protect outside environment.

Technical Data Sheet

| Model |

SCT-WB1300 |

SCT-WB1700 |

SCT-WB2400 |

| External Dimension(W*D*H)(mm) |

1300*1300*2450 |

1700*1600*2450 |

2400*1800*2450 |

| Internal Dimension(W*D*H)(mm) |

1200*800*2000 |

1600*1100*2000 |

2300*1300*2000 |

| Supply Air Volume(m3/h) |

2500 |

3600 |

9000 |

| Exhaust Air Volume(m3/h) |

250 |

360 |

900 |

| Maximum Power(kw) |

≤1.5 |

≤3 |

≤3 |

| Air Cleanliness |

ISO 5(Class 100) |

||

| Air Velocity(m/s) |

0.45±20% |

||

| Filter System |

G4-F7-H14 |

||

| Control Method |

VFD/PLC(Optional) |

||

| Case Material |

Full SUS304 |

||

| Power Supply |

AC380/220V, 3 phase, 50/60Hz(Optional) |

||

Remark: all kinds of clean room products can be customized as actual requirement.

Product Features

Manual VFD and PLC control optional, easy to operate;

Nice appearance, high-quality certified SUS304 material;

3 level filter system, provide high-cleanliness working environment;

Efficient fan and long service life HEPA filter.

Application

Widely used in pharmaceutical industry, microorganism research and scientific experiment, etc.