Industry News

-

WHAT CONTENTS ARE INCLUDED IN CLEAN ROOM CONSTRUCTION?

There are many types of clean room, such as clean room for the production of electronic products, pharmaceuticals, health care products, food, medical equipment, precision machinery, fine chemicals, aviation, aerospace, and nuclear industry products. These different type...Read more -

ADVANTAGE AND CHARACTERISTICS OF STAINLESS STEEL CLEAN ROOM DOOR

The raw material of the stainless steel clean room door is stainless steel, which is resistant to weak corrosive media such as air, steam, water, and chemically corrosive media such as acid, alka...Read more -

WHAT ARE THE WAYS TO SAVE ENERGY IN CLEAN ROOM CONSTRUCTION?

Should mainly focus on building energy saving, energy saving equipment selection, purification air conditioning system energy saving, cold and heat source system energy saving, low-grade energy utilization, and comprehensive energy utilization. Take necessary energy-savi...Read more -

PASS BOX USAGE AND PRECAUTIONS

As an auxiliary equipment of clean room, the pass box is mainly used for the transfer of small items between clean area and clean area, between unclean area and clean area, so as to reduce the nu...Read more -

BRIEF INTRODUCTION TO CARGO AIR SHOWER

Cargo air shower is an auxiliary equipment for clean workshop and clean rooms. It is used to remove dust attached to the surface of items entering clean room. At the same time, cargo air shower a...Read more -

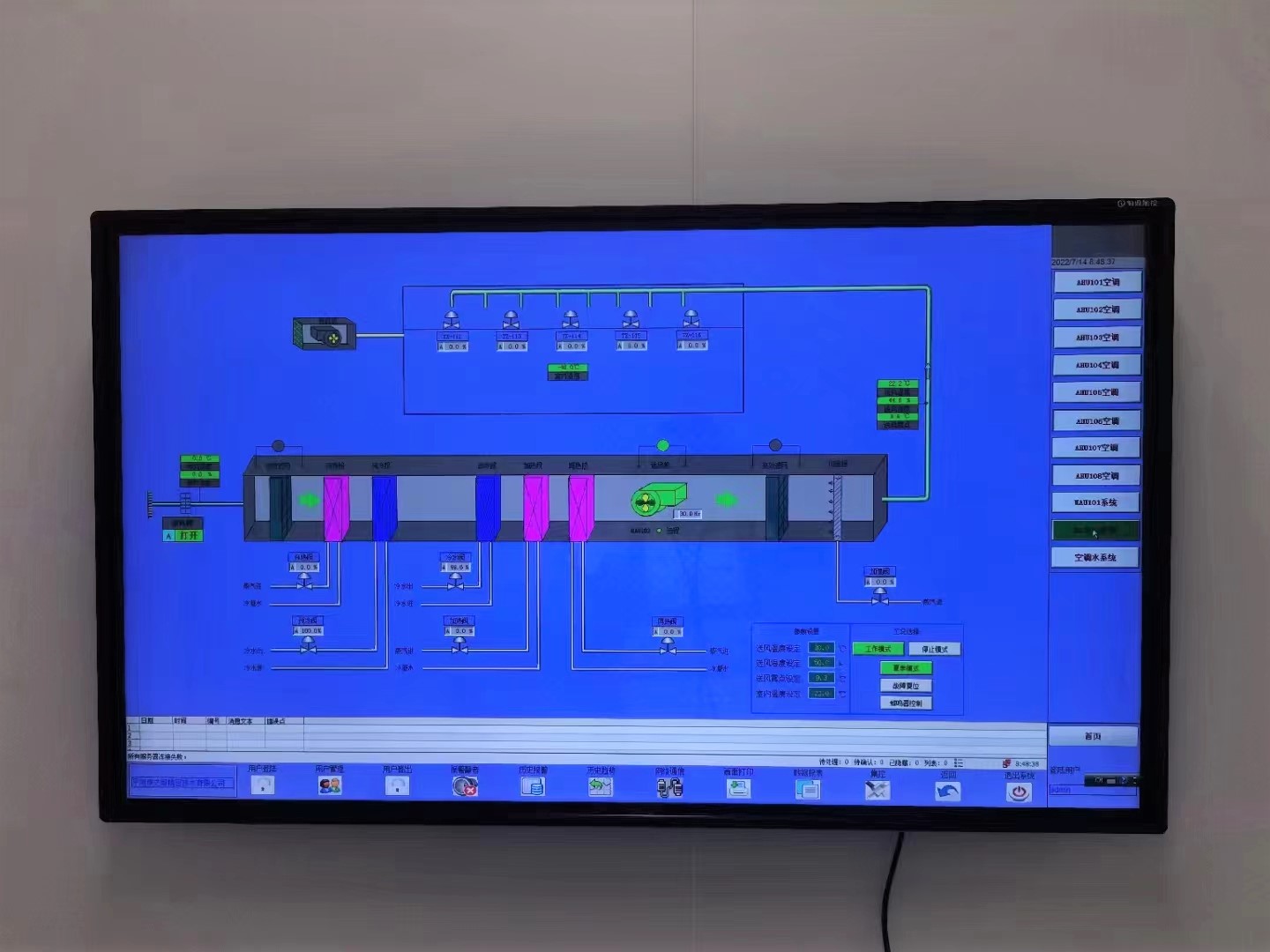

THE IMPORTANCE OF CLEANROOM AUTO-CONTROL SYSTEM

A relatively complete automatic control system/device should be installed in clean room, which is very beneficial to ensure the normal production of clean room and improve the operation and manag...Read more -

HOW TO ACHIEVE ENERGY-SAVING LIGHTING IN CLEAN ROOM?

1. The principles followed by energy-saving lighting in GMP clean room under the premise of ensuring sufficient lighting quantity and quality, it is necessary to save lighting electricity as much...Read more -

WEIGHING BOOTH MAINTENANCE PRECAUTIONS

The negative pressure weighing booth is a special working room for sampling, weighing, analysis and other industries. It can control the dust in working area and the dust will not spread outside ...Read more -

FAN FILTER UNIT(FFU) MAINTENANCE PRECAUTIONS

1. According to the environment cleanliness, replace the filter of the ffu fan filter unit. The prefilter is generally 1-6 months, and hepa filter is generally 6-12 months and cannot be cleaned. 2. Use a dust particle counter to measure the cleanliness of the clean area ...Read more -

HOW TO DETERMINE THE SAMPLING POINT OF DUST PARTICLE COUNTER?

In order to meet GMP regulations, clean rooms used for pharmaceutical production need to meet the corresponding grade requirements. Therefore, these aseptic pr...Read more -

HOW TO CLASSIFY CLEAN ROOM?

Clean room, also known as dust free room, is usually used for production and is also called dust free workshop. Clean rooms are classified into many levels based on their cleanliness. At present,...Read more -

FFU INSTALLATION IN CLASS 100 CLEAN ROOM

The cleanliness levels of clean rooms are divided into static levels such as class 10, class 100, class 1000, class 10000, class 100000, and class 300000. The majority of industries using class 1...Read more